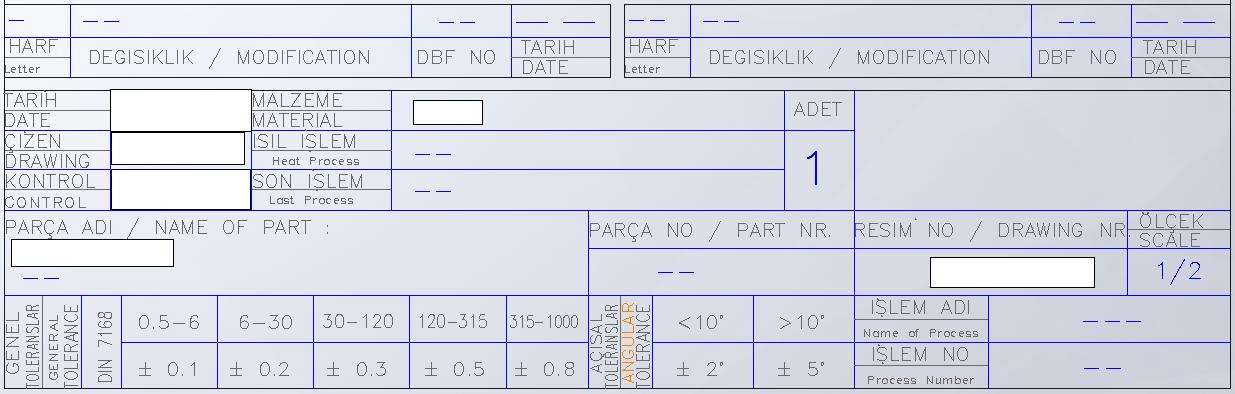

According to DIN ISO 2768-2. General tolerances for form and position are valid for form elements for which form and position tolerances are not.

DIN 6930-2 - 2011-10 - Beuth.de close-plus angle-down angle-up angle-left angle-right link-extern arrow-down arrow-right checkmark edit add date time place contact cart-small delete update history download zoom media normenticker mediathek normenticker bibliothek flatrate close menu search login cart prev next breadcrumb options email facebook-logo twitter phone help feeback print whatsapp facebook googleplus linkedin xing network flag-new flag-new-en per cent badge dinacademy payment economize shipping encoding. This standard is the technical revision of the standard which has been published in 2010-01.

This revision primarily includes the update of the normative references and the expansion of the nominal dimension ranges and the tolerances for thickness ranges or for angles on flat stamped parts. This standard is intended to simplify drawings and specifies general tolerances for linear and angular dimensions, concentricity and symmetry in four accuracy levels.

They are subdivided into f (fine), m (medium), g (coarse) and sg (very coarse). By selection of a certain accuracy level, the normal workshop accuracy shall be considered. Rukovodstvo po remontu mercedes 609d. General tolerances according to this standard are used for cold- and warm-formed stamped parts made of flat steel products. They apply if this standard is referred to in drawings or associated documents (for example, terms of delivery). This standard has been prepared by NA 026-00-03 AA 'Stanzteile' ('Stamped parts') of the Springs, Stamped Parts and Moulded Parts Standards Committee (NAFS) at DIN, the German Institute for Standardization e.

For further information about the NAFS, visit us on the Internet under www.nafs.din.de.

Dot physical form for ups drivers. ISO 6930-2:2004 specifies the requirements for weldable high yield strength steels for cold forming. It applies to plates and wide-flats, hot-rolled on reversing mills, both having a thickness between 4 mm and 50 mm (inclusive) and supplied in the normalized, normalized rolled and as-rolled delivery condition. It does not apply to weldable structural steels, whether or not of special quality, which are covered by other International Standards, namely high yield strength steel products for cold forming delivered in thermomechanically rolled condition (ISO 6930-1); structural steels (ISO 630); high yield strength flat steel products (ISO 4950-1, ISO 4950-2 and ISO 4950-3); hot-rolled steel sheet of higher yield strength with improved formability (ISO 5951).